In the optical coating process, the selection of sputtering targets has an important impact on the quality and performance of the coating. Erbium sputtering target has been widely used in the field of optical coating due to their high purity and excellent physical properties. In this paper, we will discuss how erbium sputtering target can improve the optical coating process, and we will elaborate from four aspects, namely, target properties, coating process, performance optimisation and application prospects.

Characteristics and Advantages of Erbium Sputtering Target

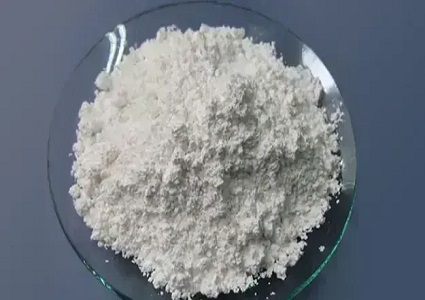

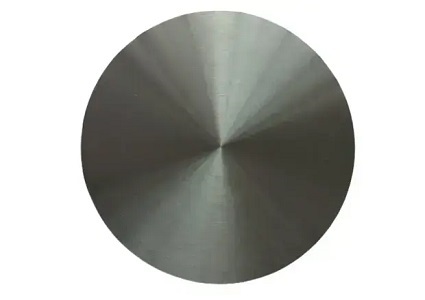

Erbium sputtering target has become an ideal choice for optical coating process because of its high purity, low impurity content and excellent physical properties. Firstly, high purity erbium sputtering target can ensure the purity and stability of the coating layer and improve the optical properties. Secondly, erbium sputtering target has low melting and boiling points, which is conducive to precise control during the coating process. In addition, erbium sputtering target has high densities and small grain sizes, which contributes to the formation of uniform and dense coating layers.

Application of Erbium Sputtering Target in Optical Coating Process

In the optical coating process, the application of Erbium Sputtering Target is mainly reflected in the following aspects: First, through magnetron sputtering technology, the erbium sputtering target atoms or ions deposited on the surface of the substrate, the formation of a coating layer with specific optical properties; second, the use of erbium sputtering target's excellent performance, adjusting the refractive index of the coating layer, transmittance, and other parameters, in order to meet the needs of different optical systems; third, through the optimization of coating process parameters, such as sputtering power, sputtering power, and sputtering parameters, to meet the demand for different optical systems. Thirdly, by optimising the coating process parameters, such as sputtering power and sputtering time, the uniformity and stability of the coating layer can be further improved.

In practice, erbium sputtering target has significant advantages in improving the optical coating process. Firstly, the high purity of erbium sputtering target ensures the purity and stability of the coating layer and improves the optical properties. Secondly, the low melting and boiling points of erbium sputtering target allow for precise control during the coating process, reducing energy consumption and costs. In addition, the high densities and small grain sizes of erbium sputtering target contribute to the formation of a uniform and dense coating layer, which improves the performance of the optical system.

Performance Optimisation and Future Prospects

In order to further improve the application of erbium sputtering target in the optical coating process, the following aspects can be optimized: firstly, optimize the preparation process of erbium sputtering target to improve the purity and density of targets; secondly, study the influence of different sputtering parameters on the performance of the coating layer to achieve precise control; thirdly, explore the preparation methods and application areas of new erbium sputtering target to expand the application scope of erbium sputtering target in the optical coating process. The third is to explore the preparation method and application field of new erbium sputtering target to expand its application scope in optical coating process.

In the future, with the continuous development of optoelectronic technology, optical coating process will face higher requirements and challenges. Erbium sputtering target, as an important material in optical coating process, will continue to play its advantages in improving optical performance and reducing cost. At the same time, with the continuous emergence of new materials and the continuous progress of preparation technology, the performance and application fields of erbium sputtering target will be further expanded and deepened.

In summary, erbium sputtering target has a wide range of application prospects in optical coating process due to their high purity, low impurity content and excellent physical properties. By optimising the preparation process, studying the influence of different sputtering parameters on the performance of the coating layer, and exploring the preparation methods and application areas of new erbium sputtering target, the application of erbium sputtering target in optical coating process can be further improved, and a greater contribution can be made to the development of optoelectronic technology.

English

English